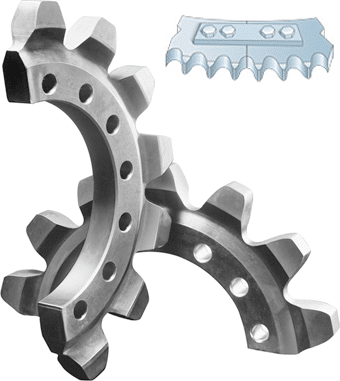

For Ease of Transportation or Installation

For very large ring sprockets, a single-piece mounting surface may become impractical or unwieldy and thus require Segmented Sprocket Components.

Segmented sprockets are more practical for large sprocket assemblies when there are issues with:

- Transportation

- On-site installation

- Need for periodic repair of sprocket profiles

When flame machining segmented ring sprockets, Cogmatic adds unique alignment notches so each segment will align perfectly — each and every time.

Cogmatic has extensive experience splitting large sprockets. Combining that background with many custom solutions for our customers’ large-diameter sprocket challenges, Cogmatic has developed joining methods that assure consistent tooth profiling and tooth spacing are maintained.

With over 60 years of experience, we’d be happy to work with you to develop manufacturable ways to make large sprockets that you can put on a truck and ship to your customer.

Segmented sprockets enable more feasible installations, as well as future maintenance or re-installations.

Related Info

A more recent segmented project involved working with one customer on an extra large, lap-jointed gear. In this case, segments were bolted together before the teeth were cut. In the following video, see the 18 foot diameter gear bolted together and the teeth being cut in the assembly. Read Case Study about this 18′ Segmented Gear. Learn more about our Segmented Gears.